Foam is created when gas is introduced and trapped within a solution that contains surfactants. It can consist of large bubbles at the surface of the solution (macrofoam) or small bubbles distributed throughout the solution (microfoam). In either case, it can cause issues within the products and equipment in which it is formed, such as lower product quality, inconsistent product density, and machine damage.

Antifoam and defoaming agents are key to preventing and controlling foam and avoiding the problems associated with it. Both compounds minimize or eliminate foam formation. However, they achieve this goal in different ways; antifoams are surfactants that prevent foam from forming in the first place, while defoamers are surfactants that control existing foam levels by stopping the bubbles from stabilizing.

There are two things an antifoam or defoamer must have to work: an entry coefficient greater than zero and a spreading coefficient greater than zero. These qualities allow the compound to enter the interface between the air and lamella (i.e., the bubble wall) and then enter the bubble wall in a process known as “bridging the film”. As it spreads, the bubble wall thins and, eventually, ruptures.

Beyond the above properties, an antifoam or defoamer can vary in many ways. For example, it can have a silicone or non-silicone composition, be aqueous or non-aqueous, and come in liquid or powder form. This broad selection enables industry professionals to choose a foam control product that meets their exact application requirements. However, it can make it challenging to identify which one best suits their needs. Below, we cover the key factors to keep in mind when selecting an antifoam or defoaming agent.

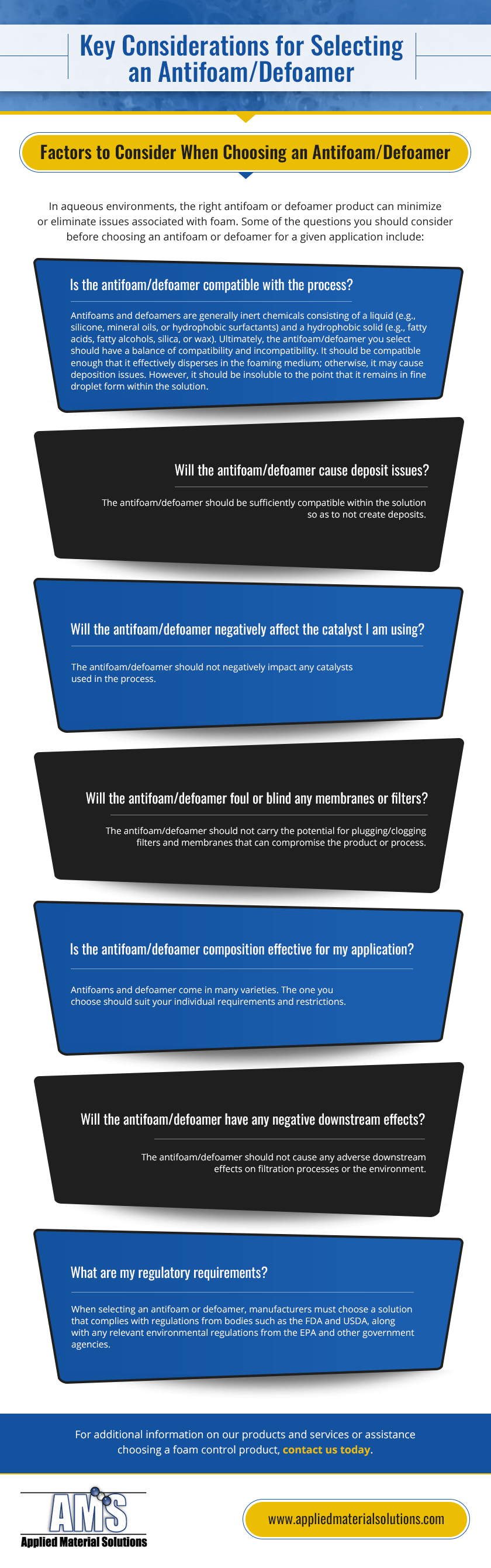

Factors to Consider When Choosing an Antifoam/Defoamer

In aqueous environments, the right antifoam or defoamer product can minimize or eliminate issues associated with foam. Some of the questions you should answer before choosing an antifoam or defoamer for a given application include:

- Is the antifoam/defoamer compatible with the process? Antifoams and defoamers are generally inert chemicals consisting of a liquid (e.g., silicone, mineral oils, or hydrophobic surfactants) and a hydrophobic solid (e.g., fatty acids, fatty alcohols, silica, or wax). Ultimately, the antifoam/defoamer you select should have a balance of compatibility and incompatibility. It should be compatible enough that it effectively disperses in the foaming medium. Otherwise, it may cause deposition issues. However, it should be insoluble to the point that it remains in fine droplet form within the solution.

- Will the antifoam/defoamer cause deposit issues? The antifoam/defoamer should be sufficiently compatible within the solution so as to not create deposits.

- Will the antifoam/defoamer negatively affect the catalyst I am using? The antifoam/defoamer should not negatively impact any catalysts used in the process.

- Will the antifoam/defoamer plug up any membranes or filters? The antifoam/defoamer should not carry the potential for plugging/clogging filters and membranes that can compromise the product or process.

- Is the antifoam/defoamer composition effective for my application? Antifoams and defoamer come in many varieties. The one you choose should suit your individual requirements and restrictions.

- Will the antifoam/defoamer have any negative effects on downstream conditions? The antifoam/defoamer should not cause any adverse downstream effects.

The answers to these questions must be weighed appropriately. In some cases, you must compromise on a solution.

Contact the Antifoam and Defoamer Experts at AMS Today

If you’re looking for an experienced foam control product supplier, turn to the experts at AMS! Equipped with extensive experience providing foam control solutions for a wide range of industries and applications and a broad selection of antifoam and defoamer products, we have what it takes to help you achieve your foam control goals. For additional information on our products and services or assistance choosing a foam control product, contact us today.

Comments are closed