About AMS

Applied Material Solutions offers high quality antifoam products, treated silicas, chemicals, and excellent customer service. AMS is the parent company of the Trans-Chemco “TCI Foam Control” brand, Performance Process Inc. (PPI), and Nottingham Company.

In 1991, Performance Process, Inc. (PPI) was founded in Mundelein, Illinois to produce fumed and precipitated treated silicas. Nine years later we installed a new state-of-the-art treated silica production unit at our Nottingham Company facility in Atlanta, Georgia, which more than doubled our capacity and reduced delivery time for our customers in the Southeast. In 2015, AMS purchased PPI, and in 2016 we expanded our silica production and consolidated facilities to our Burlington, WI plant.

Applications

Our fumed and precipitated silicas are used in a wide range of applications that include adhesives, agriculture, cable gels, coatings, cosmetics, defoamers, fire extinguishers, foods, greases, inks, paints, plastics, polyester resins, silicone rubber, silicone sealants, toners, and more.

Benefits

The benefits of fumed and precipitated silica are diverse. It is an ingredient that works as an adsorbent, and it provides anti-setting, anti-sagging, anti-setoff, anti-blocking, and reinforcement. It encourages the free flow of powders, improvements in mechanical and optical properties, pigment stabilization and dispersion, and print definition. In addition, improvements are achieved when it is used for processability, hydrophobicity control, thickening, thixotropy, rheology control, and suspension and stability behavior.

Excellent Quality

The foundation of every product we develop is its formulation, and ours lead the industry in accuracy, consistency and performance. In our cutting edge laboratory we have the equipment needed to ensure that procedures are followed meticulously while testing and regulating our formulations. Our attention to detail throughout the process results in substantial savings for our customers in both time and costs.

Collaboration

It is essential that we collaborate with our customers at every step in the formulation process, from initial discussion through development, installation, production, and performance evaluations. For us, working closely together is the reason for our success.

Hydrophobic Silica—Fumed & Precipitated

Adsorbent and Carrier

Adsorb gaseous, liquid or solid materials and act as a carrier to allow conversion of liquid and pastes into powder, making them considerably easier to dose and handle.

Applications

- Coatings & paints

- Pharmaceuticals & cosmetics

- Polyester resins & gel coats

- PVC based plastics

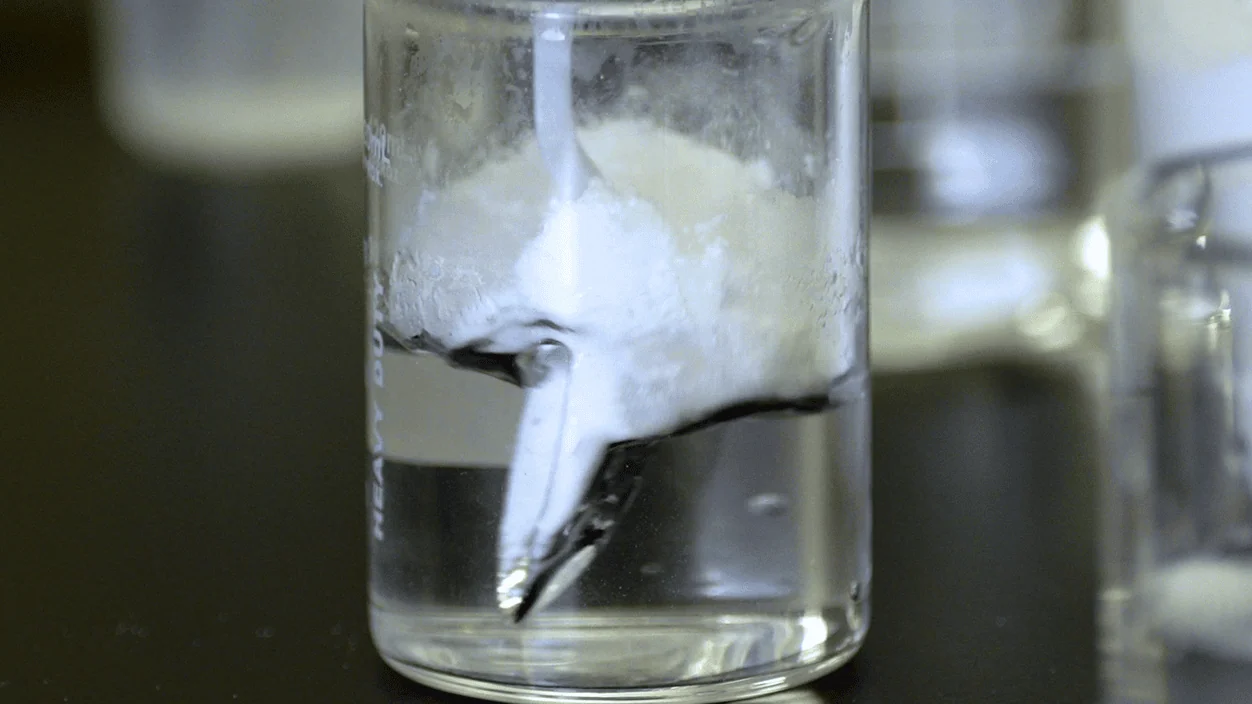

Defoamers and Antifoams

- Food—direct and indirect applications

- Paints and coatings

- Inks

- Adhesives

- Paper

- Textiles

Electrostatic Charge Effect

Reduce the tendency of plastic powders to acquire a negative electrostatic charge, eliminating characteristics that are undesirable.

Applications

- Batteries

- Coatings & paints

- PVC based plastics

Free Flow and Storage

Greatly increase the free flow and storage stability of powdered substances that have a tendency to cake.

Applications

- Coatings & paints

- Defoamers & antifoams

- Pharmaceuticals & cosmetics

- Polyester resins & gel coats

- Printing inks

- PVC based plastics

- Fire extinguisher powder

- Table salt

- Tomato powder

- Tablet powder blends

- Plastic powders

- Toners

High Temperature Insulation

Outstanding thermal insulation properties due to the fact that amorphous silicon dioxide has a very low solid state conductivity

Applications

- Cable gels

- Rubber & rubber compounding

- Thermal insulation

Providing Improvements for Many Products

Printer and Copier Toner

Improve the flow characteristics and charge stability and enhance the resolution and print quality of toners.

Applications

- Printing inks and toners

Reinforcement of Elastomers

Improve mechanical properties, such as tensile strength, elongation at break, and tear resistance, and help control the influence of temperature on mechanical properties.

Applications

- Adhesives & sealants

- Rubber & rubber compounds

- Molding, sealing, & casting compounds

Suspension, Dispersion and Grinding

Prevent or delay sedimentation of solids in liquid systems, re-disperse settled sediments without problems, and break down solid particles and prevent them from recombining.

Applications

- Coatings & paints

- Resins containing fillers

Thickening and Thixotropy

Particles restore original viscosity when in a state of rest, reversing thickening with a minimum amount of energy.

Applications

- Adhesives & sealants

- Cable gels

- Greases

- Polyester resins & gel coats

- Resins containing fillers

Storage and Stability

Remains chemically stable when stored under dry conditions, protected from volatile substances, and used within two years.

Hydrophobic Silica—Fumed

Applications for Fumed and Precipitated Silica

- Adhesives

- Agriculture

- Cable gels

- Coatings

- Cosmetics

- Defoamers

- Fire extinguishers

- Foods

- Greases

- Inks

- Paints

- Plastics

- Polyester resins

- Silicone rubber

- Silicone sealants

- Toners

Benefits

- Adsorbent

- Anti-blocking

- Anti-sagging

- Anti-setting

- Anti-setoff

- Free flow of powders

- Hydrophobicity control

- Mechanical and optical properties improvements

- Reinforcement

- Pigment stabilization and dispersion

- Print definition

- Processability improvements

- Rheology control

- Thickening

- Thixotropy

- Suspension and stability behavior

AMSil™ Hydrophobic Precipitated Silica

Properties

| Product | Specific Surface Area (BET) (m2/g) |

Average Particle Size (µm) |

Bulk Density (lb/ft3) |

pH | Form | Hydrophobicity Level |

|---|---|---|---|---|---|---|

| 35 | 120 – 140 | 6 – 7 | 8 – 9 | 8 – 9 | Powder | Standard |

| 35 FGK | 120 – 140 | 6 – 7 | 8 – 9 | 8 – 9 | Powder | Standard |

| 355 | 120 – 140 | 6 – 7 | 8 – 9 | 8 – 9 | Powder | Med high |

| 358 | 120 – 140 | 6 – 7 | 8 – 9 | 8 – 9 | Powder | Highest |

| 66 | 140 | 4 | 8 – 9 | 10.5 max | Powder | Standard |

| 66 FGK | 140 | 4 | 8 – 9 | 10.5 max | Powder | Standard |

| 665 | 140 | 4 | 8 – 9 | 10.5 max | Powder | Med high |

| 668 | 140 | 4 | 8 – 9 | 10.5 max | Powder | Highest |

| 70 | 100 – 110 | 7 | 8 – 9.5 | 8 – 9 | Powder | Standard |

| 70 FGK | 100 – 110 | 7 | 8 – 9.5 | 8 – 9 | Powder | Standard |

| 705 | 100 – 110 | 7 | 8 – 9.5 | 8 – 9 | Powder | Med high |

| 708 | 100 – 110 | 7 | 8 – 9.5 | 8 – 9 | Powder | Highest |

| 80 | 80 | 12 | 8 – 10 | 8 – 9 | Powder | Standard |

| 80 FGK | 80 | 12 | 8 – 10 | 8 – 9 | Powder | Standard |

| 805 | 80 | 12 | 8 – 10 | 8 – 9 | Powder | Med high |

Applications

| Products | Defoamers & Antifoams |

Rheology | Powders | Food & Food Additives |

Fire Extinguishers |

Resins | Plastics | Agriculture | Anti-Caking Active Filler |

|---|---|---|---|---|---|---|---|---|---|

| 35 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 35 FGK | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 355 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 358 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 66 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 66 FGK | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 665 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 668 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 70 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 70 FGK | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 705 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 708 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 80 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| 80 FGK | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 805 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

Applications

| Products | Adhesives | Defoamers & Antifoams |

Silicone Rubber |

Sealants | Paints & Coatings |

Plastics | Printing Inks & Toners |

Cable Gels & Gel Coats |

Cable Compound |

Plant Protection |

Epoxy Resins |

|---|---|---|---|---|---|---|---|---|---|---|---|

| H22 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

For additional information, or to challenge us to meet your specific formulation needs, please

contact us today.